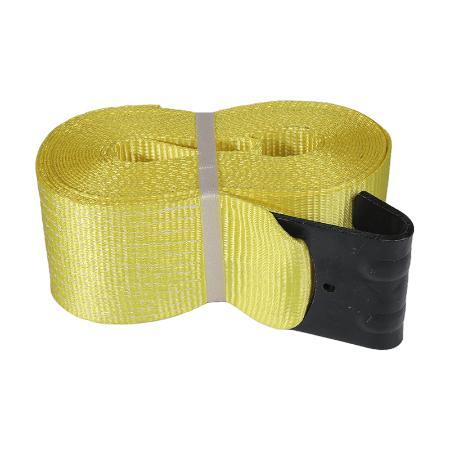

Endless webbing sling is adaptable to all three types of hitches and can be used for choker or basket lifts.Never exceed rated capacity, and take into consideration the effect of hitch angle and tension on sling capacity reduction. Keep foreign materials, such as dirt, grease, grit and metal chips off slings to prevent internal abrasion.Flat webbing endless slings can be made from either nylon or polyester and are one of the most commonly used types of lifting slings. The material doesn’t make a difference for most applications, as all webbing will be strong enough to lift your load. However, the type of webbing may matter if you’re working in an environment that can damage web slings. This includes abrasion, exposure to acids or alkalis, high/low temperatures and UV light degradation.

Endless lay eye slings are able to rotate on the load, which spreads out the bearing points and reduces wear. They are a versatile choice for choker, basket or vertical hitches and come in both standard and custom capacities, with a wide range of sizes available. Each sling is clearly labeled with its rated capacity per ASME B30.9 standards. Inspect slings regularly for any signs of damage, such as abrasion, and avoid using them beyond their rated capacity. For maximum safety, all slings should be checked by a qualified person before each use.For most lifting applications, the web sling material doesn’t make a difference in quality, capacity or strength. However, if the sling is used in a chemically-active environment, then the choice of nylon or polyester can have an impact on longevity. Nylon is unaffected by grease and oil while polyester offers resistance to many acids and bleaches.

Endless webbing slings are versatile as they can be rigged in vertical, basket and choker hitches. They also allow for rotation of the load contact points, reducing wear and increasing sling life.The length of the sling is another factor that affects its strength. Longer slings will be more prone to abrasion than shorter slings, as the webbing may rub against itself or other equipment or loads. It’s also important to consider the rated capacity of the sling, which should be based on the weight of the load and the type of hitch. Overloading, uneven loading or failure to consider the effect of the hitch angle and tension on rated capacity can lead to internal damage that can reduce sling life.A web sling must be protected from damage and must be inspected regularly. A qualified person should look and feel for any visible signs of damage such as a reduction in the sling’s elasticity and strength. Holes, cuts, snags, and knots in the webbing are also indicative of damage.

The use of webbing slings in harsh work conditions is to be expected and will cause the webbing to degrade over time. Generally, this degradation will not affect the sling’s capacity or quality, but in chemically active environments this can be a different story.It is important to avoid shock loading (rapid acceleration or deceleration of the load) as this can overload a sling and lead to unplanned release of tension, loss of load control and severe injury or death. Shock loading can also cause damage to rigging and/or equipment. Avoid this by using the proper rigging procedures, and never allow your crew to stand under or near a load.All slings should be inspected regularly to ensure they are safe for use. This is usually done every six months by supervisors or a designated employee. Defective slings should be removed from service and replaced immediately. Regular inspections can help prevent accidents and injuries due to improper use of web slings.

English

English Español

Español Deutsch

Deutsch